As an innovative manufacturer of electric powersports vehicles, Taiga Motors needed a way to bridge the gap between their CAD data and their service network. Their goal was simple but critical: make it easy for Service Partners to identify and access parts without adding unnecessary organizational overhead.

“We wanted a lean, high-quality catalog experience that connected our CAD and ERP data to our Service Partners,” said Paul Achard, Co-founder and VP of Engineering at Taiga Motors.

Zea Offers Flexible, Cost-Effective and Lean solution

After evaluating several options, Taiga selected Zea’s 3D parts catalog platform. The decision was based on Zea’s flexibility, cost-effectiveness, and strong alignment with Taiga’s need for a lean CAD-to-catalog workflow.

“Zea really offered the most cost-effective way to get from our CAD dataset to the catalog, and they were also very adaptable in listening to our needs,” Achard explained. “We wanted to give our Service Partners access to parts with a high-quality but lean and user-friendly experience.”

Zea’s platform enabled Taiga to:

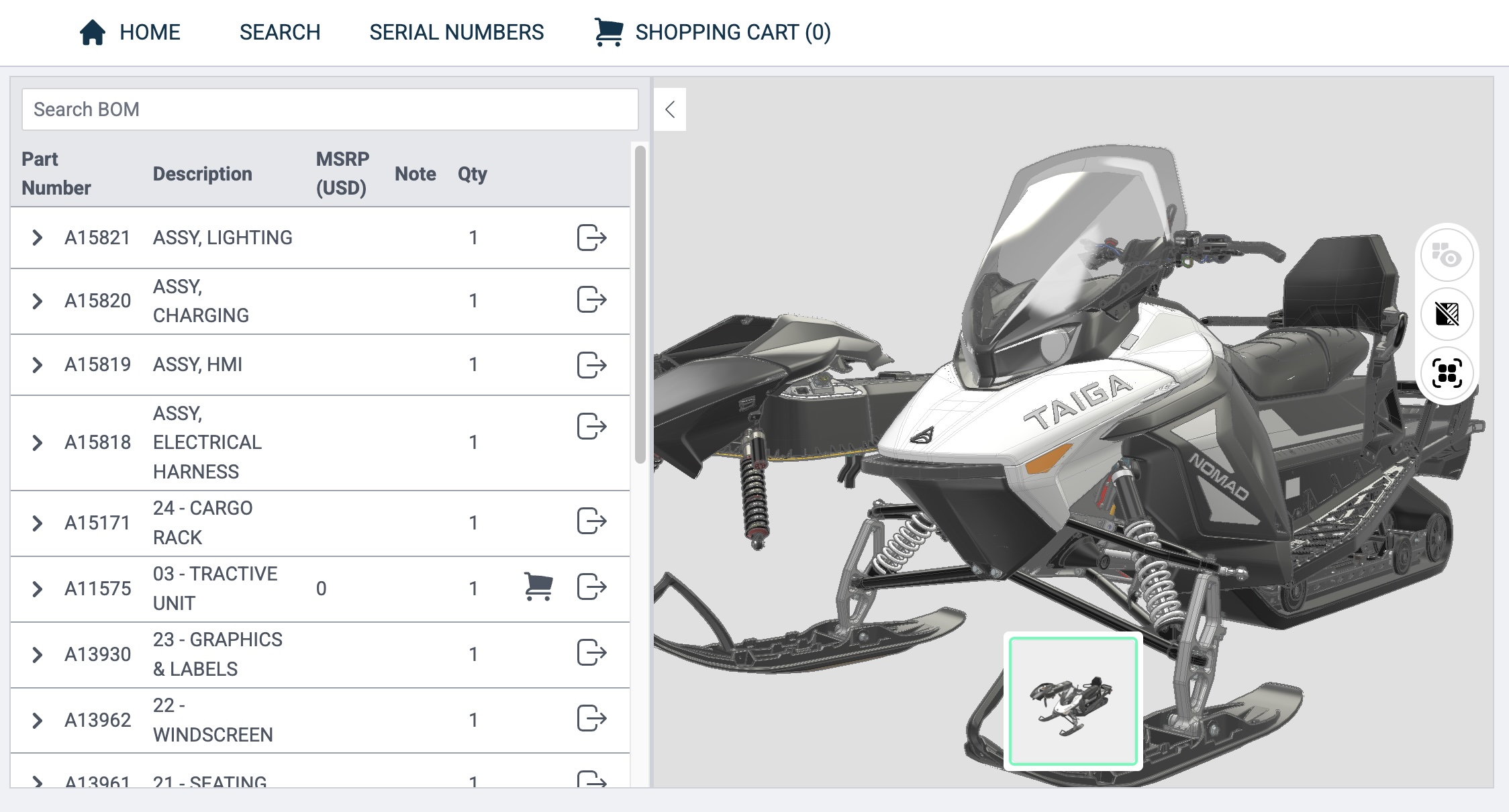

- Publish interactive 3D catalogs from CAD and ERP data

- Easily manage serviceable vs. non-serviceable parts

- Filter out sensitive IP and proprietary components

- Keep the catalog updated in real time with minimal friction

A Catalog Experience that Truly Wowed!

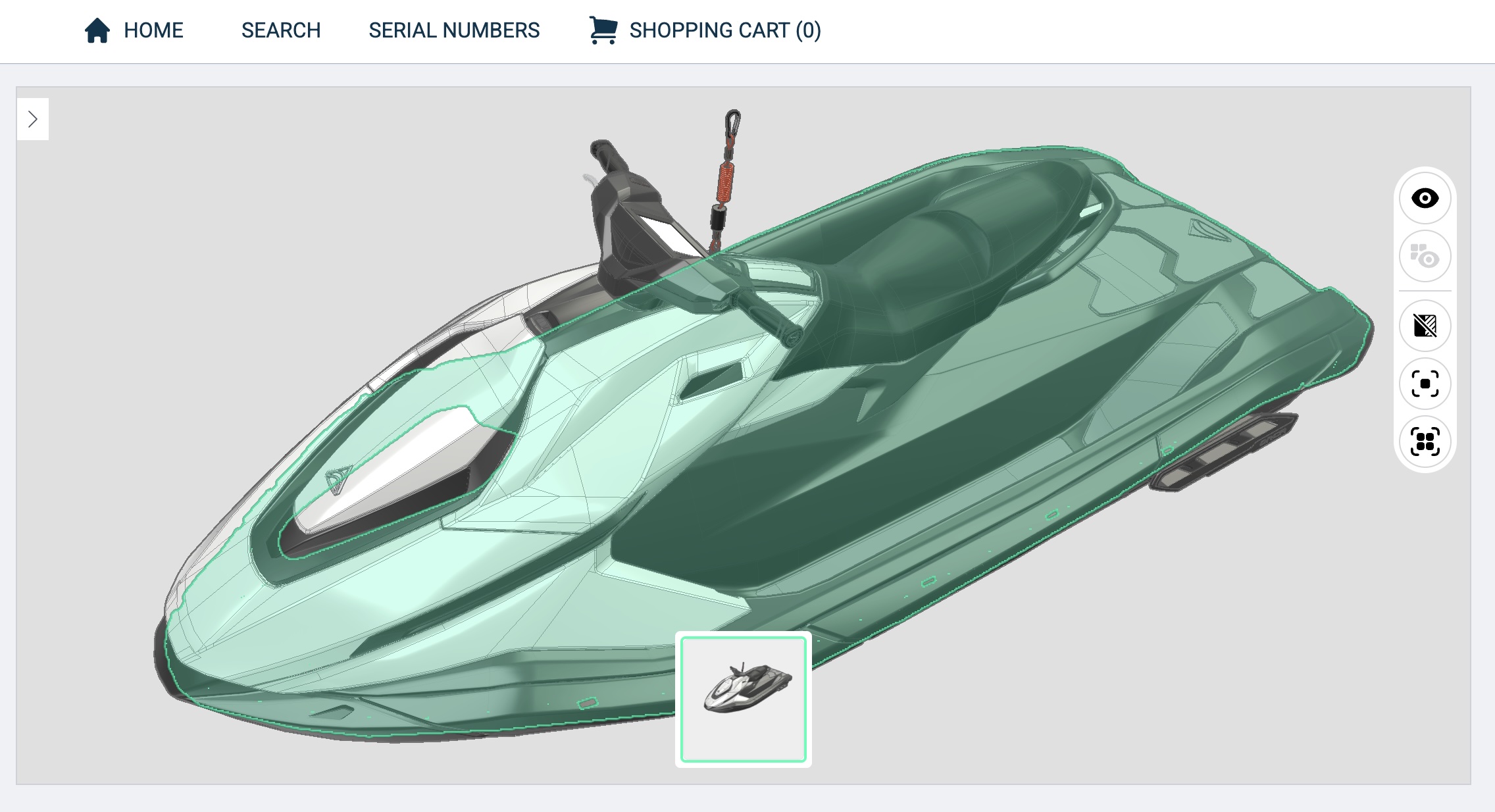

The impact was immediate. “The ‘Wow’ moment came when we opened the Orca catalog and saw our vehicle rendered beautifully in 3D, with an intuitive drill-down to part numbers,” said Achard.

From the end-user perspective, Taiga’s service partners now enjoy a seamless parts identification and ordering experience. Internally, Zea’s platform simplifies catalog updates and minimizes overhead—key benefits for a fast-moving startup.

“Zea makes it easy to bridge the gap between our engineering and business data—connecting CAD models with part numbers and pricing—so we can deliver a seamless experience to our end users.”

“The publishing process is easy, flexible, and always synchronized with our data. That’s huge for us.”

Beyond the Catalog: A Platform for Growth

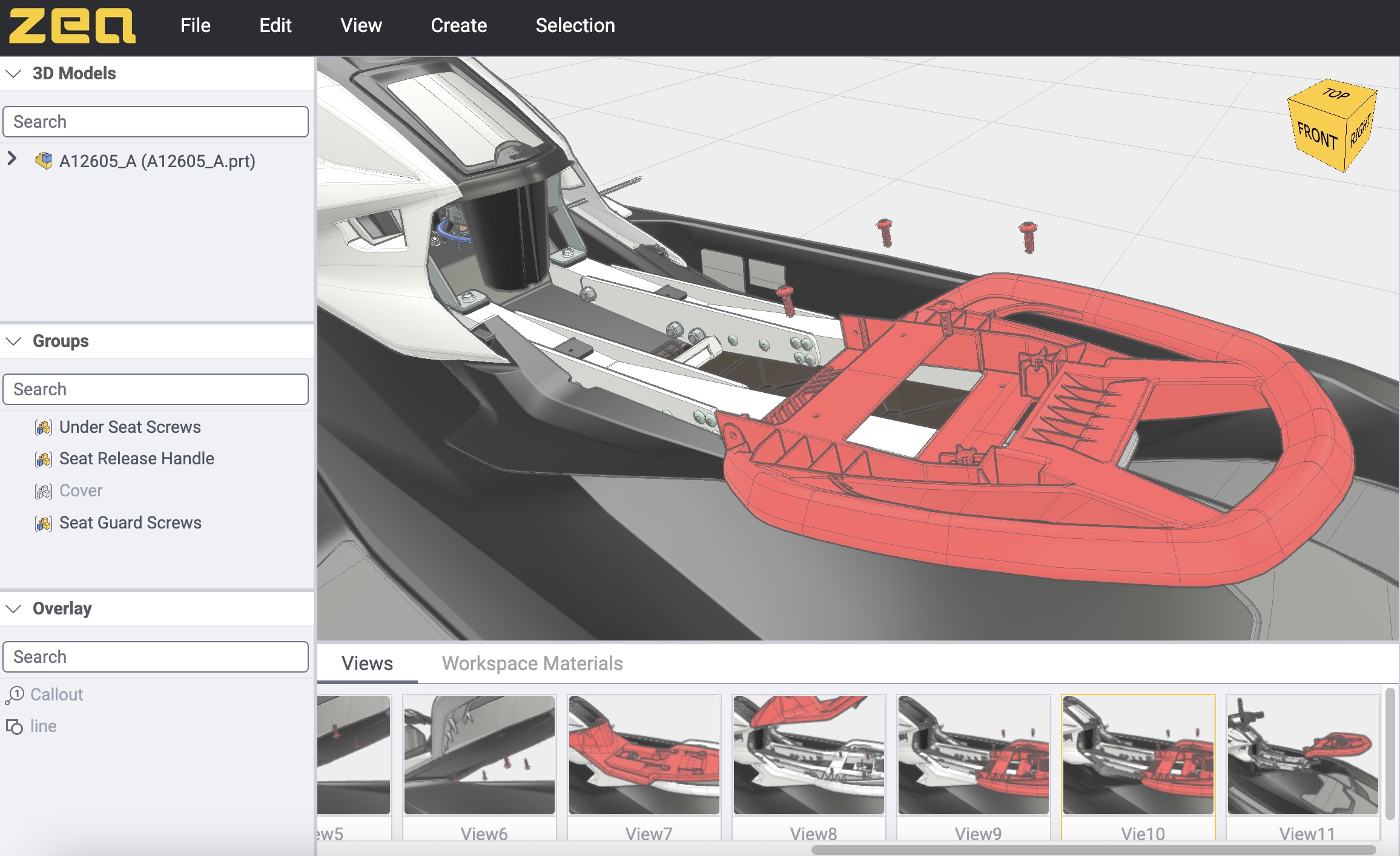

What started as a parts catalog solution is now becoming a cornerstone of Taiga’s broader service ecosystem. With Zea’s ability to connect CAD data, part numbers, and costs in one unified platform, Taiga is expanding its use into training and servicing programs.

“As soon as you have parts, part numbers, and costs, it becomes so much more than just a catalog,” said Paul Achard. “Zea is evolving into a foundation for how we support service partners, train teams, and scale operational efficiency.”

A True Partnership

For Taiga Motors, working with Zea has never felt like a typical vendor relationship. From the outset, the Zea team embedded themselves in Taiga’s journey—adapting, problem-solving, and growing alongside them.

“We feel like not just a client, but a partner,” said Paul Achard. “Zea has been with us every step of the way—listening closely, responding quickly, and continually improving their platform to meet our evolving needs.”

It’s this collaborative spirit that has made Zea not just a solution provider, but a trusted extension of the Taiga team.

The Recommendation

“Zea is a powerful product and it’s a team we trust. They’ve helped us build more than a catalog; they’ve helped us build a foundation for scalable service and support.”

Taiga Motors set out to build a lean, modern catalog experience—and with Zea, they achieved that and more. From simplifying complex data integration to delivering a visually stunning and intuitive parts platform, Zea has become an essential partner in Taiga’s growth. As the company expands its use of the platform into training and service programs, one thing is clear: Zea isn’t just powering catalogs—it’s helping Taiga redefine what’s possible in after-sales support.