“I have seen lots of innovations over my 26 years here. ZEA’s platform really tips the scale.” Cliff Anderson, Almon

“No one harvests innovation like Trebro.” It’s not just a tagline—it’s a commitment backed by decades of engineering excellence, hands-on problem solving, and world-class customer support. Since introducing the first successful automatic stacking turf harvester in 1990, Trebro has been on a mission to lead the turf industry with cutting-edge machines like the AutoStack 3 (AS3)—a one-man harvesting powerhouse designed for maximum productivity and comfort.

But even the most advanced machine is only as powerful as the support behind it. That’s where Zea and product support solutions partner Almon come in.

The Challenge: Complex Machines, Even More Complex Parts Identification

Trebro’s machines may be designed for simplicity in the field, but behind the scenes, they’re intricate systems with hundreds of components. For years, identifying the right replacement part meant calling Barry—the company’s legendary parts expert—and trying to describe the issue over the phone.

“There’s only one Barry,” said Hunter Shields, Trebro’s Technical Lead. “And everyone relied on him to identify parts based on vague descriptions. It just wasn’t scalable.”

The team needed a solution that could empower customers and technicians to identify parts visually—without relying on memory, guesswork, or legacy PDF manuals.

Zea’s Self-Serve 3D Solution

In partnership with Almon Inc, a leading solutions provider of technical publications, training and product support applications for manufacturers, the Zea platform was leveraged to create a whole new experience for customers and employees.

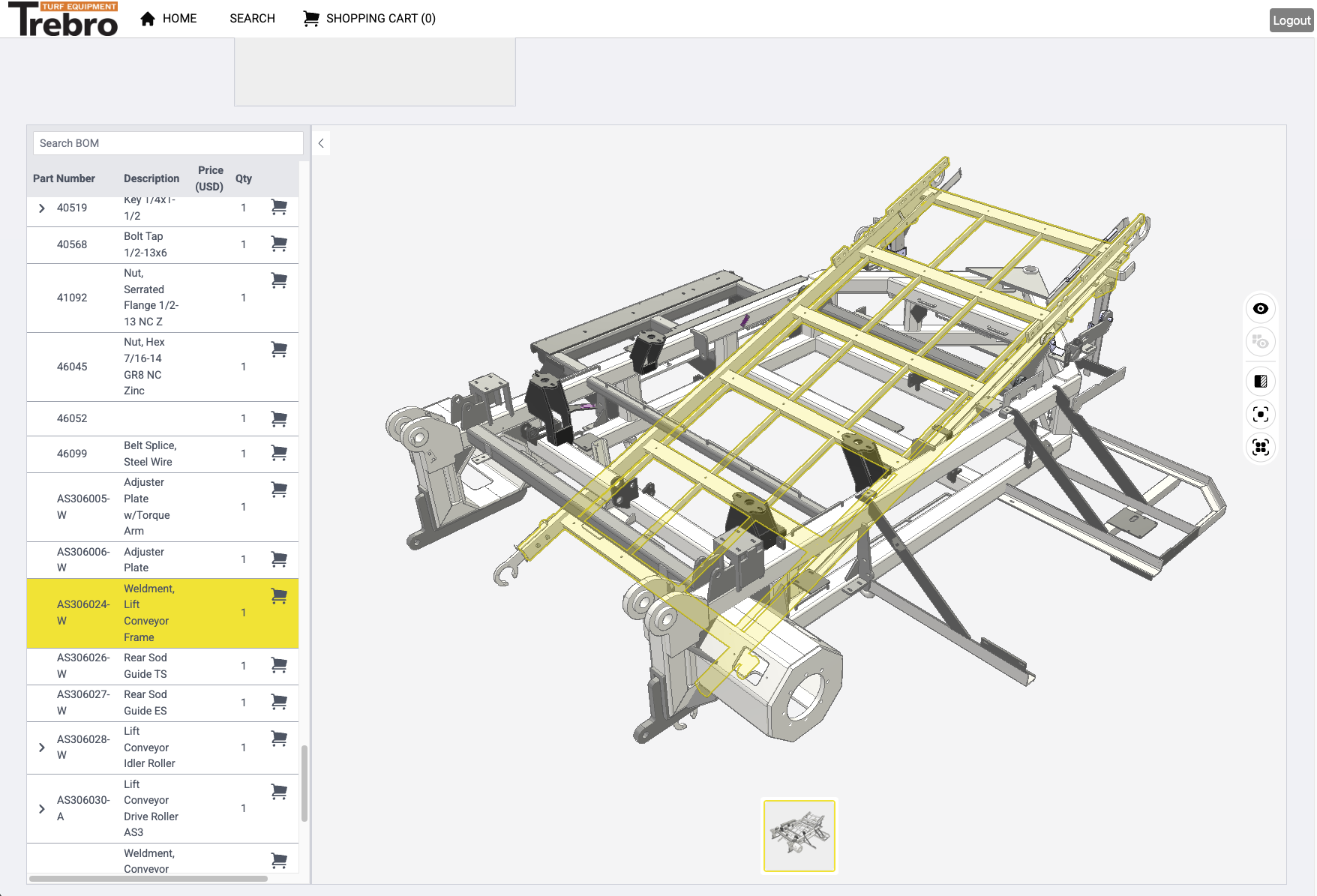

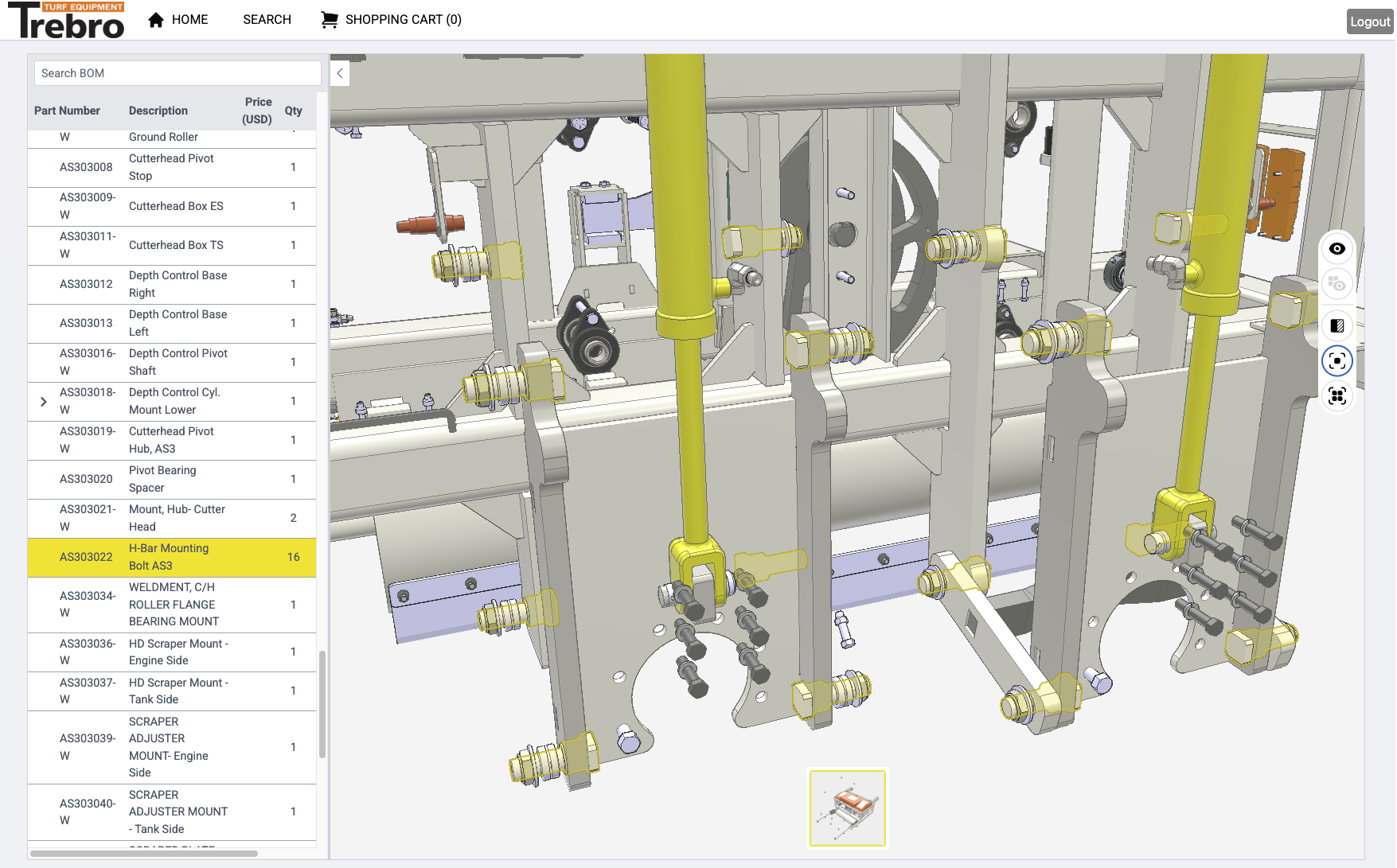

With Zea’s interactive 3D parts catalog platform, Trebro now provides a self-serve website that connects customers directly to the machines they own—virtually. Instead of describing parts over the phone, and trying to match that to a part number, users can explore a live 3D model of the equipment, pinpoint exactly what they need, and build a request for a quote with confidence.

“Zea bridges the gap,” said Shields. “Even if you’re not an engineer, you can navigate a model, find the part, and move on. That’s powerful.”

This has transformed Trebro’s support experience:

- Field service technicians can visually diagnose problems on-site

- Customers can identify parts without needing engineering knowledge

- Saves company employees valuable time and energy

Real Results: Time Saved, Teams Empowered

“ZEA took a nearly impossible task for one of our clients and delivered an amazing solution for their parts catalogs,” says Cliff Anderson, Client Solutions Manager at Almon. “It is the difference between night and day.”

Trebro’s internal teams, especially service techs and managers, have embraced the shift. What was once a bottleneck has become a streamlined, collaborative process that saves time, reduces frustration, and enables faster repairs in the field.

“People are excited,” Shields added. “They feel the innovation. And they love that Zea isn’t a static tool—it’s evolving with us.”

Full-Machine Interactivity and Beyond

The Trebro team is already working to bring full 3D models of its AutoStack 3 and TSR harvesters online with Zea, enabling customers to interact with the complete machine—not just subassemblies. Zea’s powerful platform is capable of visualizing massive products fluidly in real-time, typically unheard of in a web-based 3D CAD engine.

“Zea’s just fun to work with,” Shields concluded. “It’s solving real problems in real time—and that kind of progress gets people excited.”

As Trebro continues to lead the turf industry with machinery that’s built for the future, Zea and Almon are proud to be helping power that next level of service and support.