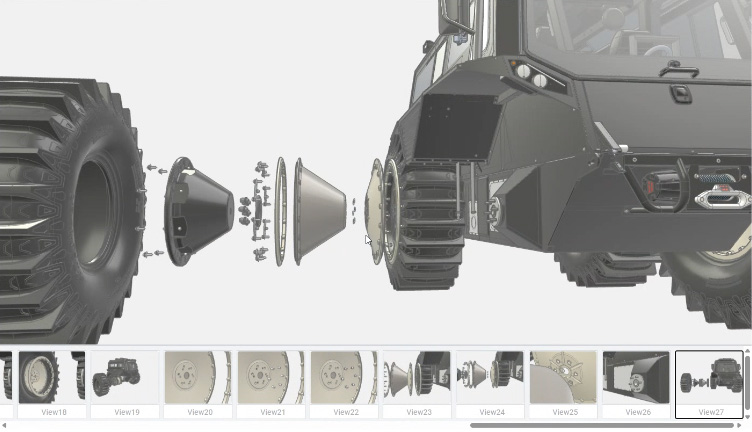

“There used to be thick manuals—you had to flip through pages to find anything. Now, one 3D view in Zea shows you everything. That image tells you 10,000 words of what to do.” David Lord, ZEAL Motor

ZEAL Motor is no ordinary vehicle manufacturer. Founded in 2017, the company builds amphibious, all-terrain “Fat Trucks” for industries ranging from disaster relief to national defense. ZEAL Motor has carved out a unique space in the world of off-road utility. But rapid growth brought complex challenges—particularly in communicating technical information for service and assembly.

That’s where Zea came in.

A Better Alternative to traditional CAD software

Like many manufacturers, ZEAL Motor originally relied on traditional CAD software to create technical documentation. But these legacy software proved cumbersome, expensive, and difficult to scale. “We had to take screenshots, put them into Word docs, export PDFs, print them, and then reprint any time there was a product change,” said David Lord, Director of Customer Service at ZEAL Motor.

Frustrated with this outdated process, Lord searched for a more flexible and efficient solution—and found Zea.

“We used to hand out PDFs and hope the techs figured it out. Now, with Zea, they get 3D interactive instructions right through our dealer portal website. It’s easier to train them, and they actually enjoy using it.” David Lord, Director of Customer Service, ZEAL Motor

Digital Twins That Drive Results

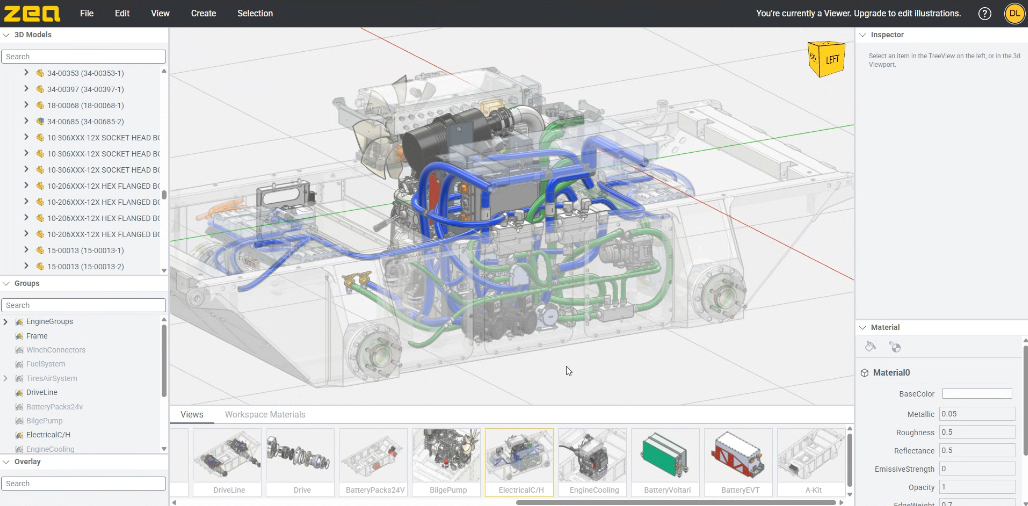

Zea’s cloud-based platform enabled ZEAL Motor to create interactive 3D service instructions, which were first rolled out through their dealer portal. Technicians could now view immersive, step-by-step guides for complex tasks—like drivetrain service or part replacement—directly in the field. The response was immediate. Field reps were more effective. Customers had fewer questions. Training times dropped.

From Service to the Shop Floor

Seeing the success on the service side, ZEAL expanded Zea’s use to manufacturing. Today, it’s integrated into the shop floor workflow, guiding technicians through assembly with clarity never before possible. “There used to be thick instruction manuals,” Lord said. “Now one 3D view tells you more than 10,000 words.”

Zea also helps ZEAL stay agile. Technicians can easily adjust to part changes or custom builds, and designers are incentivized to keep CAD data clean.

“Some of these vehicles are extremely complex—multiple cooling systems, five electric motors, a diesel generator… and Zea loads the entire 3D model in the browser without breaking a sweat. That’s impressive.” David Lord, Director of Customer Service, ZEAL Motor

Built for Agility and Innovation

ZEAL is a company built on innovation and speed. From amphibious drivetrain configurations to border patrol vehicles that float across rivers, their product demands constant adaptation. Zea’s lightweight, browser-based platform matches that ethos.

“The beauty of Zea is it works for how we operate—fast, lean, and precise,” said Lord. “It lets us build instructions once, then deploy them everywhere—from dealers to assembly lines.”

A Trusted Technology Partner

ZEAL Motor chose Zea not just for its product, but for the team behind it. From the start, the collaboration has been rooted in responsiveness, trust, and shared problem-solving. As a fast-moving manufacturer, ZEAL values partners who help them stay lean and innovative. Zea’s team has worked closely with ZEAL—proving that great technology is built on even better relationships.

“We don’t treat this like a typical customer-vendor setup. We’re building something together,” continues Lord. “Zea focuses on making a world-class 3D platform—we focus on building the machines. It’s a true collaboration.”